The Garnet & Mica mine of Zenober Iranian Company is located in Kerman province, 15 km from east of Sirjan city. Its communication route is from the Sirjan-Baft asphalt road, 15 kilometers long after Najaf Shahr city, and after one kilometer of the asphalt road, we reach the Garnet mine area of Zenober Iranian Company.

The amount of defnite reserve calculated for this mine is 34.5 million tons of defnite reserve of garnet schist ore with an average weight percentage of 14.45% of garnet and mica with an average weight percentage of 27.6.

Given the high reserves and potential of the Zenober Iranian Company›s garnet mine, as well as based on studies and investments made, extraction from the reserves of this mine has been planned in two phases – medium-term and long-term, for the two minerals: garnet and mica.

According to the performance and approach of Zenober Iranian Company in relation to the garnet mine, in the first phase, has been constructed a factory with an annual capacity of 80.000 tons of garnet production.

The factory will be expanded to produce garnet with a capacity of 140.000 tons. The mica processing plant with a capacity of 120.000 tons per year will be constructed the medium-term phase.

It is worth mentioning that the Zenober Iranian Company›s garnet mine in Sirjan not only aims to meet the country’s domestic needs and achieve self-sufficiency in importing garnets required by the sandblasting, waterjet, and mica industries, but it will account for 10 to 15 percent of the world’s garnet and mica production in the long term.

The common applications and consumptions of Garnet in the industries are briefly described as following:

Sand-blasting

Common uses of Garnet for sandblasting:

Waterjet

In waterjet technique, the abrasives are ejected from the nozzle head in an aqueous solution with a pressure of about 55000 Psi (38.7 m.kg/m2). The size of the nozzle head depends on the materials used for cutting and the cutting conditions, but usually the opening diameter is from 0.23 mm to 2.8 mm.

Its first feature is that it does not generate sparks and provides safety in environments where there is a potential for explosion. The second feature is that it works almost without dust.

The flexibility and accuracy of the advanced automatic waterjet system makes it possible to use it in a large number of industrial factories and cut various types of materials, including steel, aluminum, plastic, wood, composite materials, glass, stone, cement, ceramic and cardboard. The global market of this industry, needs 220,000 tons of Garnet per year.

Coated abrasives

Coated abrasives are composed of graded abrasive grains that are glued on sheets of paper or fabric and are used to polish and smooth the surface of various artifacts. The main abrasives for this application are: Aluminum, Silicon carbide, Silica, Garnet. The type and size of abrasives are determined by their final use.

These days, the use of Garnet as a coated abrasive is limited to the woodworking industry, which has a market consumption of about 5000 tons per year in the United States of America.

Papers and fabrics with Garnet coating are mainly used for wood wear and also for polishing leather, hard rubber, plastic, glass and softer metals.

Finishing and polishing

Precious abrasive powders have made great progress compared to coated abrasives and are used for precise and uniform polishing of electronic parts, special glasses and other precision products. Abrasive materials that compete with this material include Diamond pieces, Silicon carbide, Aluminum slag and Silica powder.

Also, cleaning by Garnet reduced the polishing time. Garnet creates a suitable surface and is cheaper than many other abrasive materials. The weak points of using Garnet are the slow work speed and the relatively high consumption of materials. If the grains are too small, it will cause scratches on the surface and if they are too soft, it will waste the Garnet.

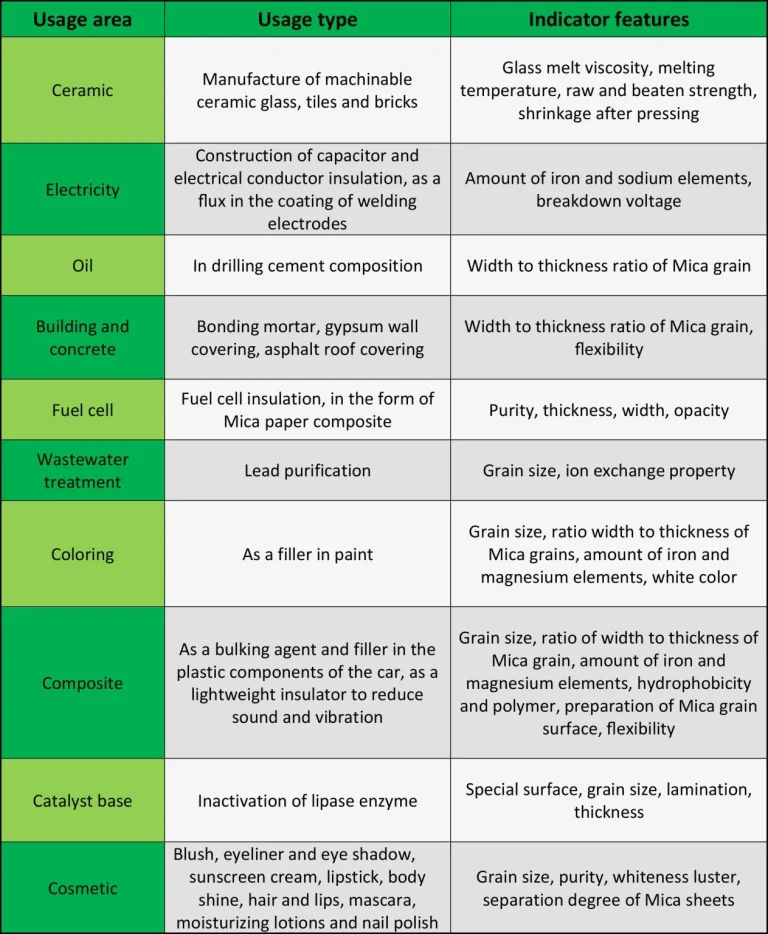

The types of Mica minerals have different uses, especially in the industry, which is presented in the following table, a summary of the Mica’s usage in different areas and the characteristic of the relevant index.